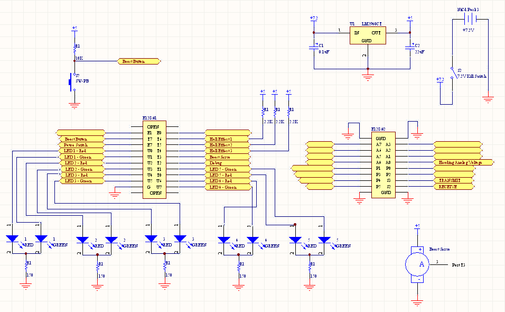

Electrical Design: Bike (Capture Vehicle Controller)

The schematic of our bike electronics is below. Click on the image for a full size PDF.

The heart of our Capture Vehicle Controller uses the E128 Microcontroller in order to receive sensor inputs, send out messages to the boat via Xbee radio, and causes indicators on the Bicycle Control Panel to change depending on the status of the boat and game. A rotary hall effect sensor is used to measure the rotation of the handle bars in order to provide the boat with a heading. 3 Hall Effect Sensors are used to detect the speed and direction of the bicycle wheel. When a magnet passes in front of the hall effect sensor, the signal line is grounded. The 3 hall effect sensors had to be triggered in the right order for direction to be measured correctly. Lastly, a button was cleverly disguised inside a bicycle bell which when pulled would cause the boat to ramp up the motors to the maximum speed.

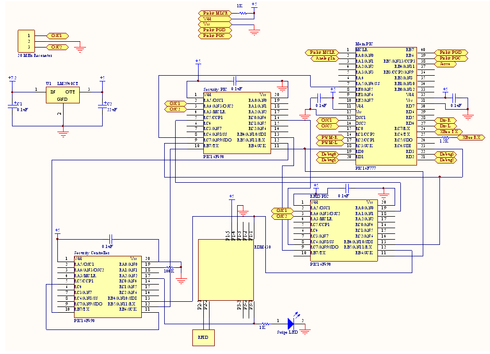

Electrical Design: Boat (Atoll Capture Vehicle)

The schematic of our boat electronics is below. Click on the image for a full size PDF.

The Main PIC used was the PIC16F777 followed by two PIC16F690s to read the RFID Code and to act as a SPI Master.The PICKit3 shown in the schematic was used to In-Circuit Program/In-Circuit Debug and was done by wiring the PICKit 3 to these appropriate ports on the PIC16F777.

The Main PIC used was the PIC16F777 followed by two PIC16F690s to read the RFID Code and to act as a SPI Master.The PICKit3 shown in the schematic was used to In-Circuit Program/In-Circuit Debug and was done by wiring the PICKit 3 to these appropriate ports on the PIC16F777.

The boat schematic shows how the network of PIC microcontrollers are configured with reference to the actual ports.

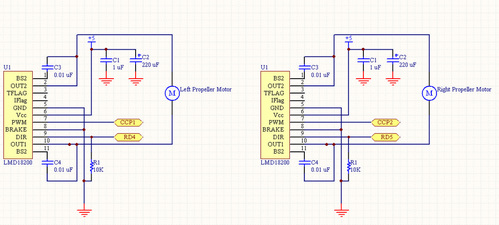

LMD18200s were used to drive the left and right propeller motors. These would be driven via PWM and direction signals outputted by the PIC16F777.

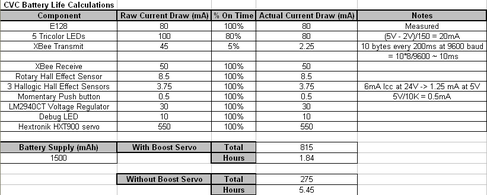

CVC Battery Life Calculations

Summing all of the current draws and making some assumptions about the % On Time yields the Estimated Battery Life for the CVC. If we turn off our boost servo (which was not used to meet project requirements), the CVC should last almost 5.5 hours on one 7.2V NiCad battery.